The Ultimate Guide to Advanced Foam Control Techniques and Solutions

Wiki Article

The Duty of Foam Control in Enhancing Item Top Quality and Performance

Foam control is an often-overlooked yet vital component in the search of item top quality and functional performance throughout diverse industries. By efficiently managing foam formation, companies can not just boost the uniformity of their formulas however also tackle functional obstacles that can hamper efficiency. This discussion will discover the complex effect of foam on both product integrity and manufacturing procedures, increasing important questions concerning the methods that can be utilized to optimize foam control. As we take into consideration these effects, it ends up being clear that the stakes are greater than they may initially show up.

Comprehending Foam Formation

Foam development is a complicated sensation that can substantially impact product top quality and operational performance across different sectors. Comprehending these variables is crucial for handling foam properly.The liquid's thickness and surface area tension play essential roles in foam stability. Surfactants, as an example, can reduce surface stress, promoting bubble formation however additionally enhancing foam security, which can be bothersome in certain applications. Mechanical anxiety, temperature level variations, and the visibility of impurities can worsen foam generation, making it crucial to monitor these elements during manufacturing procedures.

Industries such as food and drink, drugs, and chemical production need to be specifically alert regarding foam control. By understanding the hidden systems of foam development, organizations can implement targeted methods to alleviate its results, consequently maintaining functional performance and making certain regular item efficiency.

Effect On Product High Quality

The existence of foam can considerably compromise product quality throughout numerous markets. In producing processes such as food and beverage, drugs, and cosmetics, too much foam can bring about irregular product formulations. For instance, in food manufacturing, foam might trap air, affecting texture and taste, which can eventually change consumer assumption and contentment.In addition, foam can prevent the uniformity of paints and coatings, causing problems like bubbles and uneven surfaces. In pharmaceutical applications, foam can interfere with the exact dosing of fluid medicines, possibly affecting therapeutic efficiency and client safety and security. These high quality issues not just diminish completion product's charm but can likewise lead to expensive recalls and damages to brand reputation.

Furthermore, the visibility of foam can complicate top quality control steps, making it hard to achieve consistent outcomes and specific measurements. Efficient foam control not just reduces these threats but likewise boosts overall product high quality by ensuring that formulas fulfill stringent market standards. By purchasing foam control methods, firms can guard their products, boost customer fulfillment, and preserve an one-upmanship in the marketplace.

Operational Challenges From Foam

Effective procedures in various industries can be drastically disrupted by the existence of foam, which poses several obstacles throughout production processes. Foam can hinder mixing and response times, hampering the efficiency of chemical procedures. In markets such as food and drink, foam development can bring about imprecise fill degrees, resulting in product waste and incongruities in packaging.

In settings where hygiene is vital, such as pharmaceuticals and food handling, foam can make complex cleansing procedures, producing surprise reservoirs for impurities. This not only increases quality worries however likewise can lead to conformity issues with regulatory requirements.

In addition, the mental effect on operators can not be overlooked; extreme foam can create a chaotic job setting, bring about lowered morale and productivity. In recap, dealing with the functional challenges presented by foam is essential to preserving performance and item top quality in numerous sectors.

Strategies for Reliable Foam Control

How can markets effectively mitigate the obstacles posed by foam? Efficient foam control techniques are essential for enhancing product top quality and functional efficiency.

In enhancement to chemical services, process optimization plays an essential duty in foam management. Industries can examine and adjust specifications such as blending rate, temperature level, and pressure to lessen foam generation. Carrying out equipment alterations, like installing foam-breaking devices or adjusting container layout, can better help decrease foam degrees.

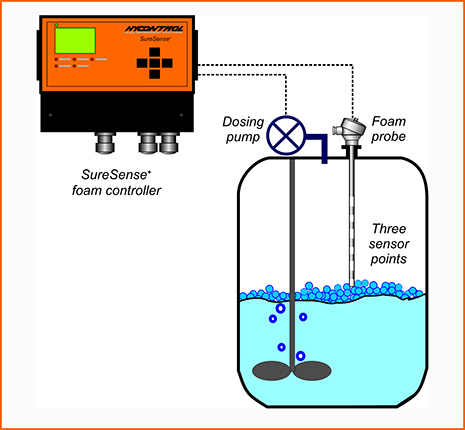

Regular tracking and analysis of foam behavior within production procedures are likewise important. Making use of advanced sensing units and analytics can supply real-time information, enabling prompt treatments and changes. Personnel training is just as vital; ensuring that workers are well-informed about foam dynamics and control methods can bring about positive foam management.

Situation Studies and Market Applications

While numerous industries deal with one-of-a-kind challenges associated with foam control, study reveal that tailored methods can substantially improve both product top quality and functional effectiveness. In the pharmaceutical industry, for example, a leading manufacturer implemented a custom-made visit this site foam control approach that decreased foam formation throughout fermentation procedures. This innovation not just enhanced yield by 15% yet also minimized contamination threats, making sure higher item stability.Similarly, in the food and drink market, a significant dairy products producer challenged excessive foam throughout pasteurization - Foam Control. By introducing a specialized antifoam representative, they reduced handling time by 20%, which straight translated to boosted throughput and decreased power intake. The application of foam control measures ensured regular product appearance and taste, enhancing brand commitment

In the chemical manufacturing market, a study highlighted the successful application of foam control in wastewater treatment procedures. The implementation of a real-time surveillance system allowed drivers to readjust antifoam dosage dynamically, bring about a 30% reduction in chemical use and boosted effluent quality.

These study show the varied applications of foam control across markets, stressing its crucial function in boosting product high quality and functional efficiency.

Final Thought

In final thought, efficient foam control is important to click improving product top quality and functional performance throughout different industries. Ultimately, focusing on foam control adds to official source enhanced performance, safeguarding brand name credibility, and raising customer contentment, highlighting its importance in quality guarantee within producing processes.Foam control is an often-overlooked yet vital element in the search of product high quality and operational efficiency throughout diverse industries. Team training is similarly essential; ensuring that employees are experienced about foam characteristics and control methods can lead to proactive foam monitoring.

While numerous industries deal with distinct obstacles associated to foam control, case research studies reveal that customized methods can dramatically improve both item high quality and functional effectiveness (Foam Control). In the pharmaceutical field, for instance, a leading supplier executed a personalized foam control method that reduced foam formation throughout fermentation processes.In final thought, effective foam control is important to boosting product top quality and operational effectiveness throughout various markets

Report this wiki page